Introduction

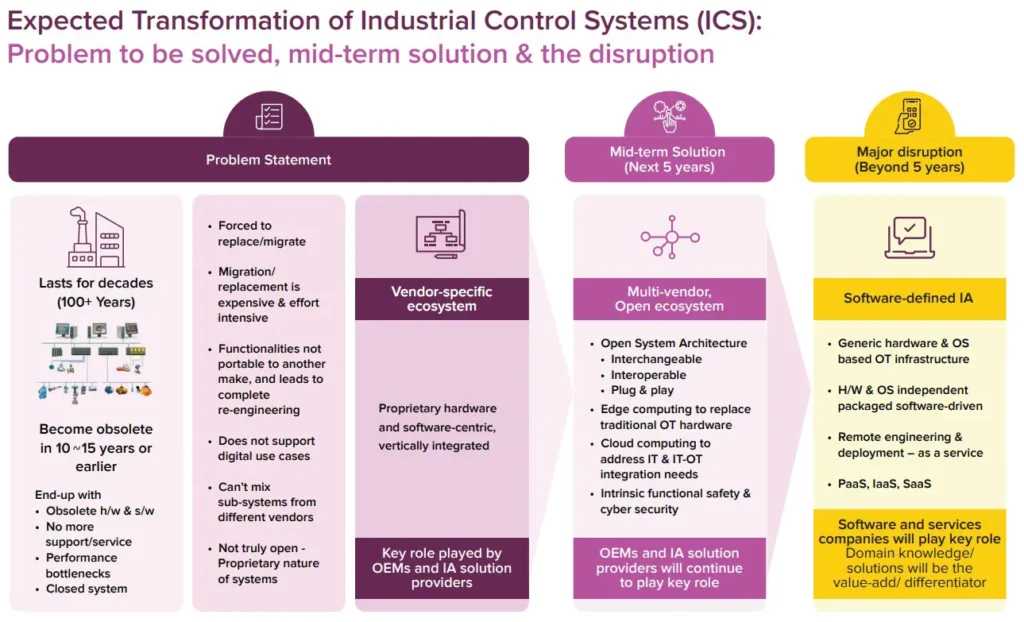

Today, the ICS (Industrial Control Systems) landscape is undergoing a fundamental transformation, driven by four big shifts, which will empower original equipment manufacturers (OEMs) and end-users alike to embrace a new era of ICS. Open Process Automation Forum (OPAF) of The Open Group is working on the industry standards (OPAS – Open Process Automation Standard) for next-gen control systems. Multiple initiatives by various industry consortiums are on to develop and pilot OPAS based system. The progress of these pilot projects to implement OPAS based systems clearly indicates that soon the industry will see the shift towards software-based ICS a reality.

- From proprietary systems to open, interchangeable, interoperable systems

- The first major shift is the transition from proprietary systems to open, interchangeable, interoperable systems. Introduction of the concept of DCN (Distributed Control Node) and OCF (OPAS Connectivity Framework) of OPAS brings a great deal in making the future control systems open, interoperable and interchangeable. OCF built on the new OPC UA standard makes the system not just open but truly interchangeable and interoperable. This will eventually permit the end users to have multi-vendor systems to gain maximum benefit and also easily upgrade the systems getting over the vendor-lock in scenarios. The COPA (Coalition of Open Process Automation), a consortium building the OPAS based pilots, has made significant progress by demonstrating robust interoperability, portability, and interchangeability across a multi-vendor OPA system using the OCF.

- From hardware-driven to software-driven systems

- The second significant shift is from hardware-driven to software-driven systems. This change eliminates vendor lock-in, allowing users to experiment with different software and edge computing hardware providers to achieve the best possible outcomes for their unique requirements. Similar shifts have occurred in the telecommunications and automotive industries, where the focus has moved from hardware to software as the primary driver of innovation and value creation.

- Software companies are partnering with OEMs and non-profit organizations like to accelerate this evolution towards software-driven control systems. “Intel is a big believer in software-defined control systems,” said Richard Kerslake, industrial control and robotics at Intel. “Today, you think of [automation in] discrete boxes, such as PLCs and HMIs. Here, we break the bonds between hardware and software, which makes the whole lifecycle easier in terms of deployment and updates. And having the flexibility to choose best-of-breed hardware is about protecting your investments.”

- From unsecure systems to highly secure systems

- The third big shift is the transition from unsecure to intrinsically cyber secured systems. With the increasing adoption of IoT and Industrial IoT technologies, the importance of cybersecurity has never been greater. This has prompted end-users and OEMs to bolster the security of their ICS deployments in critical infrastructure.

- President Biden issued a memorandum on July 28, 2021, regarding the importance of cybersecurity for critical infrastructure control systems. This memorandum officially introduced the Industrial Control Systems (ICS) Cybersecurity Initiative and sets out the United States’ strategy to protect vital infrastructure, with a specific emphasis on the security and ability to withstand cyber-attacks of systems that support government functions and the private sector. The move towards open, standardized, and software-driven systems provides the foundation for enhanced security, as it allows for the elimination of vulnerabilities and better preparedness against cyber threats.

- From managing devices and systems to managing applications

- The fourth transformative factor is the shift from managing devices and systems to managing software applications. Through software containerization, applications can be abstracted from heterogeneous hardware, operating systems, and other software, improving deployment, visibility, and maintenance. Multiple industrial consortiums working on the concept of Module Type Package (MTP) of software is now converging to a consistent overall architecture.

- The combination of containerization of software and edge computing offers enormous possibilities in the field of industrial control systems. Containerization allows the software to be packaged and deployed independently of the underlying hardware and operating system, enabling efficient and consistent deployment across a variety of systems.

The role of the open group, OPAS, and Quest Global

The Open Group and Open Process Automation Forum (OPAF) are developing the standard (OPAS), for realizing the next-gen ICS. Quest Global is proud to be part of this major disruption in the industry as a member of OPAF and we are also associated with Coalition for Open Process Automation (COPA) to accelerate the realization of next-gen ICS[4]. Together, we are working to create a more open and interoperable ecosystem for ICS, supporting OEMs and end-users to adopt new technologies and solutions.

Conclusion

The future of industrial control systems is bright, with the advent of open, interoperable, software-driven and highly secure solutions disrupting the status quo. As industrial control systems experts, we at Quest Global are excited to contribute to this transformation and support our clients in their journey towards the transformation of industrial control systems. Knowledge accumulated through 25 years of experience in developing, deploying and maintaining ICS across multiple industries helps Quest Global to be at the forefront of this revolution, partnering with clients to develop and implement next-generation control systems that capitalize on these disruptive shifts. Embracing these changes, OEMs and end-users alike can break free from the limitations of traditional control systems and unlock new levels of innovation, efficiency, and security.

References:

- https://www.cisa.gov/sites/default/files/publications/ICS-Monitoring-Technology-Considerations-Final-v2_508c.pdf

- https://www.redhat.com/en/topics/containers/whats-a-linux-container

- https://press.siemens.com/global/en/pressrelease/siemens-industrial-edge-takes-benefits-cloud-field-level

- https://www.quest-global.com/news/quest-global-joins-coalition-for-open-process-automation-copa-to-enable-industry