As a mechanical engineer, I have witnessed the progression from computational fluid dynamics to the current AI revolution in industrial engineering. My background might surprise some people wondering what a mechanical engineer is talking about artificial intelligence (AI). The answer lies in understanding how domain expertise transforms raw algorithms into practical solutions for complex engineering challenges.

The foundation of successful AI implementation starts with data. Without quality data, even sophisticated algorithms fall short. This reality shapes our approach across aerospace, automotive, healthcare, energy, semiconductor, and rail industries.

Neural architectures for design space exploration

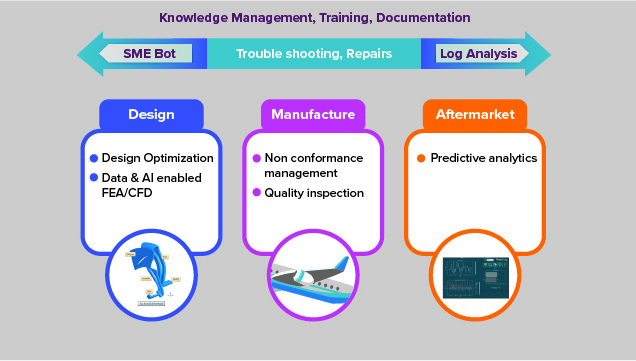

Traditional product design relied on experienced engineers mentally integrating past designs, field data, and test results. This inherently limited our exploration capabilities to a handful of design permutations. Modern neural network architectures fundamentally transform this constraint. At Quest Global, we have demonstrated how AI can enhance design optimization by evaluating millions of designs to find the most optimal one in just a few hours. This capability represents a significant advancement in how engineering teams approach complex design challenges.

We envision applying these techniques across multiple verticals, from aerospace components to semiconductor layouts. In aerospace and defense, we see tremendous potential for multiphysics optimization algorithms that could simultaneously evaluate thousands of design permutations. Such systems could manage complex interactions between weight, strength, thermal performance, and manufacturability parameters that traditionally demand weeks of iterative analysis.

For semiconductor clients, we are exploring how reinforcement learning models might optimize integrated circuit layouts against competing requirements. These algorithms could balance power consumption, signal integrity, heat dissipation, and manufacturing yield – all critical for advanced chip designs where traditional methods fall short.

Documentation creation represents another significant area where we have demonstrated AI’s value. Technical documentation traditionally consumed substantial engineering resources. We are developing specialized language models that could auto-generate certification documents, conformance reports, and system specifications directly from design data, potentially reducing documentation overhead while improving consistency and compliance.

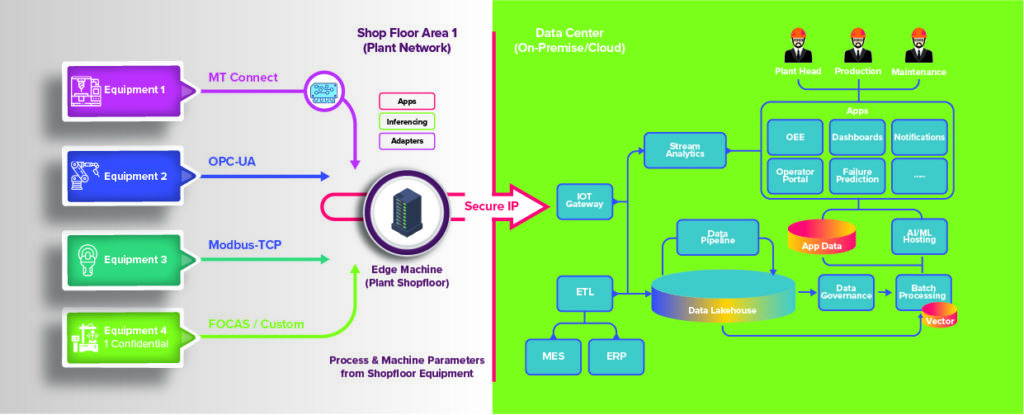

Real-time manufacturing intelligence through edge computing

IoT connects industrial equipment across manufacturing facilities, generating massive operational datasets. This continuous telemetry enables intelligent monitoring through specialized models deployed at the network edge. At Quest Global, our ThirdEye platform demonstrates our capabilities in computer vision and real-time analytics. We see significant potential to extend this technology across various manufacturing applications. In medical device manufacturing, we envision anomaly detection systems processing multimodal sensor data to identify microscopic defects invisible to human inspectors. Such convolutional neural networks could run directly on edge computing hardware, delivering sub-millisecond response times essential for production-speed quality control.

Automotive assembly lines represent another promising application area. We are exploring how computer vision systems could inspect components at full production speed, identifying subtle defects through specialized vision models trained on both real and synthetic defect images. Synthetic data generation holds particular promise for rare defect types where training examples remain limited.

Energy sector applications demonstrate another dimension where we see potential breakthroughs. Advanced transformer-based models could analyze vibration, thermal, and acoustic signatures from generation equipment, detecting pattern changes that precede failures. This predictive capability could enable maintenance interventions before failures impact operations, dramatically reducing downtime and maintenance costs.

Operational data analytics for maximum aftermarket value

The aftermarket phase generates the richest operational data across product lifecycles. Here, AI delivers immediate ROI through predictive maintenance, performance optimization, and automated technical support. In rail transportation, we foresee time-series analysis models processing telemetry from rolling stock, infrastructure, and signaling systems. These specialized algorithms could identify maintenance needs weeks before conventional approaches, enabling efficient scheduling that minimizes service disruptions while maximizing equipment availability.

Aerospace applications present exciting opportunities for digital twins that continuously update virtual models based on operational data. Such systems could simulate component performance under various conditions, predicting remaining useful life with exceptional accuracy. The simulations would incorporate actual operational patterns rather than theoretical usage models, potentially enabling safe life extension beyond conservative design limits.

For healthcare clients, we are developing equipment monitoring systems that analyze diagnostic imaging system telemetry, with the goal of identifying subtle performance degradation before clinical outcomes suffer. These models aim to distinguish between normal variations and true anomalies, enabling targeted maintenance that maximizes uptime while minimizing unnecessary service interventions.

Technical hurdles in enterprise AI implementation

Despite tremendous potential, industrial AI deployment faces significant challenges. Most manufacturing environments contain disconnected data silos, legacy systems with proprietary protocols, and incomplete historical data. Our experience spans these obstacles across multiple industries. Data quality presents the most persistent challenge in industrial AI implementation. Industrial systems often operate for decades, accumulating vast but inconsistent datasets. We are developing preprocessing pipelines to handle common industrial data issues, including irregular sampling intervals, sensor drift, missing values, and outlier detection.

Security requirements add another layer of complexity. Industrial systems demand specialized security approaches beyond consumer AI implementations. We are designing architectures incorporating model validation, execution monitoring, and anomaly detection specifically for applications where safety and reliability remain paramount. Deployment constraints present additional hurdles in industrial environments. Industrial facilities frequently operate in remote locations with limited connectivity. Our work with Small Language Models (SLMs) aims to address these limitations through optimization for deployment on resource-constrained edge devices, potentially providing sophisticated capabilities without cloud connectivity dependencies.

Autonomous agent networks for engineering workflows

Multi-agent AI systems represent what we see as the next evolution in product lifecycle management. These autonomous systems could incorporate specialized agents handling different aspects of engineering workflows, collaborating to solve complex problems with minimal human guidance.

For automotive testing, we envision autonomous agents analyzing field data, identifying edge cases human engineers might miss, and automatically generating comprehensive test scenarios. These agents could continuously refine test suites based on emerging patterns, ensuring thorough validation across the entire operational space. Similar capabilities might benefit semiconductor design. We are exploring how autonomous agents could continuously evaluate field performance data, identify optimization opportunities, and generate improved designs. Such systems could manage iterative simulation, validation, and optimization steps independently, potentially accelerating improvement cycles while freeing engineers for higher-value activities

Neural network customization for industrial applications

Developing effective machine learning systems for industrial applications requires specialized architectures beyond general-purpose AI. Our research into industrial implementations incorporates several critical elements for reliable deployment. Model architecture selection proves particularly important. While deep learning dominates many consumer applications, we believe industrial systems often benefit from hybrid approaches combining multiple techniques. We are investigating physics-informed neural networks incorporating domain constraints, ensemble methods combining multiple model types for robustness, and probabilistic models providing uncertainty quantification critical for safety applications. Feature engineering demands equal attention. While end-to-end deep learning shows promise in many fields, our experience suggests industrial applications often benefit from domain-specific feature extraction. We are developing pipelines implementing signal processing techniques specifically adapted to industrial data characteristics, potentially improving model performance on limited training datasets.

Reshaping engineering intelligence

Generative AI models specifically designed for engineering applications could enable exceptional design automation. These systems would inherently understand manufacturing constraints, material properties, and industry standards, generating designs optimized across all relevant dimensions. Edge AI capabilities continue maturing rapidly, potentially enabling sophisticated local intelligence without cloud dependencies. Specialized hardware accelerators designed for industrial edge applications could support increasingly complex models with minimal power requirements, allowing deployment across even the most constrained environments. Quantum computing integration represents perhaps the most significant frontier in our exploration. While practical quantum advantage remains emerging, our partnerships with quantum computing startups explore potential applications in materials science, complex simulation, and optimization problems previously considered computationally infeasible.

The AI engineering evolution accelerates daily. Organizations developing the technical capabilities, data infrastructure, and strategic vision to harness these technologies will define the future of engineering across all industries. At Quest Global, we continue to innovate these capabilities alongside our clients as we navigate this transformation together.